Things You'll Need

Portland cement

Water

Concrete sand

1/2 inch gravel aggregate

Water

Perlite

Vermiculite

1 pound or 5 pound coffee cans

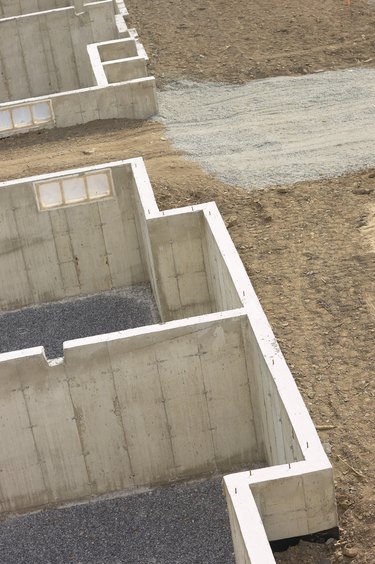

Standard concrete mixtures consist of four elements: Portland cement, sand, gravel aggregate and water. In many instances, a lightweight concrete is used to achieve a specific weight-per-square-foot. Lightweight concrete is achieved by substituting a lighter weight material for the gravel aggregate. Select an aggregate substitute based upon the final usage of the concrete pour to achieve lightweight concrete.

Step 1

Measure concrete by mass rather than volume. An easy way to do this is to create different concrete mixtures with different aggregates. Pour the mixtures in identical containers and measure the wet and dry weight of each mixture. Use containers of equal size. 1 pound or 5 pound coffee cans make workable containers for comparison.

Video of the Day

Step 2

Create a standard concrete comparison base by mixing 1 part Portland cement, 2 parts coarse sand and 3 parts gravel aggregate of 3/8 inch, 1/2 inch or 3/4 inch size. Concrete of normal density will weigh approximately 145 pounds per cubic foot when dry. Add water sparingly. Too much water will create a weak mix that will crack easily.

Step 3

Follow the standard concrete mix proportions of 1 part Portland cement, 2 parts coarse sand and 3 parts Perlite. Add just enough water to create a smooth mixture. Pour the mixture into the container you have selected. Tamp the mixture down by bouncing the container on a firm surface. Use a spatula to level the top of the container. Repeat the mixing process using various lightweight aggregates such as vermiculite, scoria, cinders or processed shale. Use an accurate scale to measure and record the wet weight of each mixture. Label each container with a black felt pen to identify the lightweight aggregate in each container.

Step 4

Allow all of the mixtures to dry for 48 hours. Weigh each container and record the dry weight of each mixture. Air-dry densities of lightweight concrete will vary greatly depending upon the lightweight aggregate used. Expect densities from 12 to 80 pounds per cubic foot.

Step 5

Use lightweight concrete to line chimneys or to create floor systems. Create and pour counter tops with lightweight concrete. Use it as bases for storage tanks or tank insulation. Lightweight concrete is used as flooring in high-rise buildings to reduce weight and has many weight-reducing applications as roofing for commercial buildings, schools and warehouses.

Video of the Day

- Concrete Mix Proportions: Lightweight Concrete Mixes

- Cellular Concrete: Structural lightweight concrete

- Flying Concrete: Lightweight Concrete

- Schundler Construction: Lightweight Concrete Mix Designs

- Everything About Concrete: What Do You Need to Know About Concrete?

- National Ready-Mixed Concrete Association: What is Structural Lightweight Concrete?