Satin and semigloss polyurethane finishes give wood surfaces shine and protection. They differ from each other in the proportions and quantities of different chemicals used. Choosing which finish to use is really a matter of personal preference in color and transparency, and the degree of durability your floors and furnishings require.

Polyurethane

Video of the Day

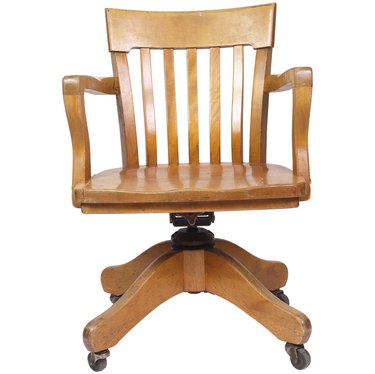

Polyurethane is an oil-based resin finish that is commonly applied to wood flooring and furniture. It is actually the base ingredient for both satin and semigloss finishes, as well as many others. Polyurethane is applied as topcoat for flooring in order to protect the wood from scratches, scuffs and other types of abrasions. It is applied to wood furniture to give it a lustrous finish. Polyurethane formulations are categorized as "urethanes," and include oil-based urethane, water-based urethane and moisture-cured urethane. Each type of formulation is available with a satin or semigloss finish.

Video of the Day

Satin and Semigloss Similarities

Satin and semigloss urethanes can be applied to all types of wood surfaces -- from flooring to furniture. In the case of flooring, the first application should be done by experienced professionals, especially on new, unfinished wood. Both satin and semigloss finishes are available in clear or amber-colored formulations. Clear finishes are better on darker woods because they have a bluish tint that could make lighter brown and warmer-hued woods look dull. Satin and semigloss urethanes are highly flammable and must be used with caution in a well-ventilated room.

Satin and Semigloss Differences

The amount of luster and shine is the biggest difference between satin and semigloss urethanes. Just as both are types of urethane, both actually begin as high-gloss finishes. Manufacturers add a flattening paste made with zinc oxide to a high-gloss formula to turn it into a satin or semigloss formula. Satin urethanes have more flattening paste, and hence, less sheen, while semigloss urethanes have less flattening paste. If you are after a more lustrous and shiny finish, you should opt for a semigloss urethane.

Types of Satin and Semigloss Formulations

Both satin and semigloss come in three types of formulations: water-based, moisture-cured and oil-based. Water-based urethanes paint on clear and dry the fastest of all three formulations. Moisture-cured urethanes come in clear and amber tones. In terms of drying time, moisture-cured urethanes are faster-drying than oil-based, but not quite as fast as water-based. Oil-based semigloss and satin urethanes are the most popular of all three types of formulas. Many people find oil-based urethanes easier to apply on the initial application, as well as when it is time to give floors or furniture a new coat of finish. Water- and oil-based urethanes have a mild odor and moisture-cured urethanes have a strong odor.