Things You'll Need

Copper sheet or wire

Detergent soap

Pickle solution or lemon juice

Large pot or crock pot

Super Spray (or other product) or clear glass paint

Copper makes a great inclusion when fused in glass, but it will oxidize and turn a dull red color during the fusing process. However, you can easily clean and prepare copper for inclusion in fused glass projects in a few simple steps.

Step 1

Cut your copper sheet or wire to the shape you want for your inclusion.

Video of the Day

Step 2

Clean your copper by washing it with detergent and water.

Step 3

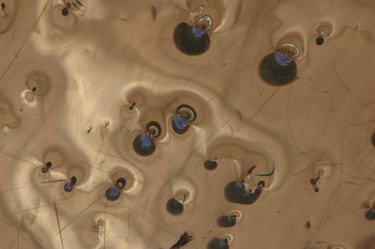

Place the copper in a warm pickle solution bath in a large pot for about 15 minutes. You can use a commercial pickle designed for metalsmithing, or just use simple lemon juice. A small crock pot is an excellent tool for pickling copper.

Step 4

Remove the copper item from the pickle using copper tongs to prevent getting any oils back on the cleaned copper. Pat dry with paper towels or use a hair dryer.

Step 5

Coat the copper on both sides with Super Spray -- a commercially avaialble chemical compound -- or similar metal-treating product. Alternately, you can use a clear glass paint to coat and protect the copper. Spray or paint the copper in one direction, then spray or paint a second coat perpendicular to the first.

Step 6

Allow the copper to dry, place your the inclusion within your fused glass design and fire according to your usual schedule.

Tip

Super Spray and similar products can be purchased at art glass stores and online.

Warning

Be sure to wear a mask when working with chemical sprays.

Video of the Day